Cellevat3d® nanofiber microcarriers and macrocarriers

Cellevat3d® nanofiber microcarriers

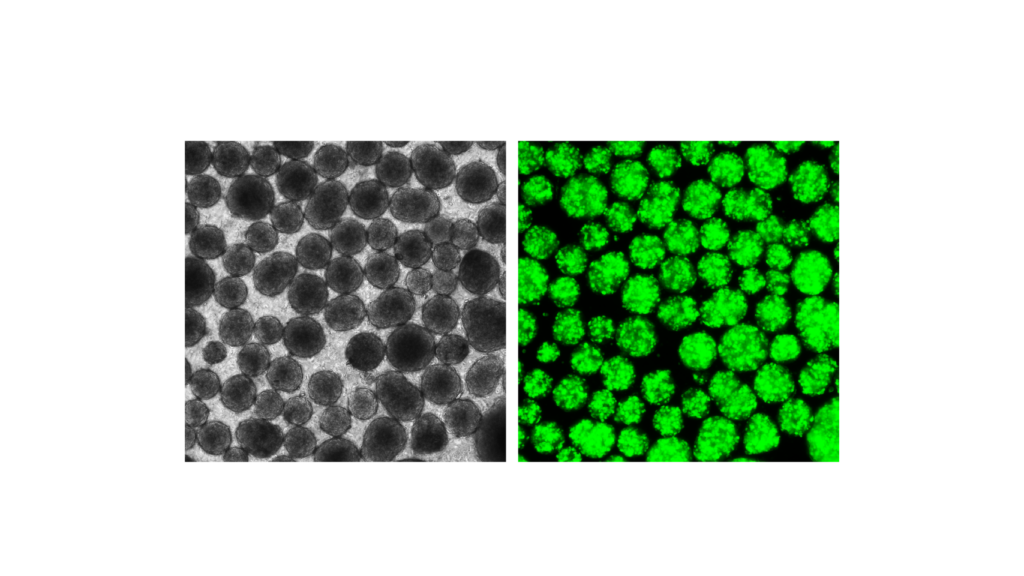

Cellevat3d® new category nanofiber-based cell culture systems designed to scale up adherent cell culture by forming homogenous spheroids that grow in suspension and generate significantly higher yield and productivity than current processes.

We are on the brink of a biomanufacturing revolution

The emergence of therapeutical biologics like cell- and gene therapy marks the beginning of a new medical era, revolutionizing treatment across several fields and offering options for previously untreatable diseases. While the field has grown rapidly and is expected to continue expanding, challenges in manufacturing, such as low productivity, poor yields, and scaling issues, drive up costs and limits patient access. It has been noted that these high development cost could stall the market unless a second “Biomanufacturing Revolution” follows, highlighting the urgent need for new disruptive, scalable, and sustainable technologies to make these therapies more affordable.1

1) World Economic Forum. Accelerating the Biomanufacturing Revolution. Whitepaper. Feb 2022

Driven by innovative cell culture technologies

As the search for more affordable therapies intensifies, so does the quest for novel cell culture technologies aimed to improve yield, overall productivity and decrease cost of production. The microcarrier market is one of the fastest growing in the industry, projected to rise from EUR 2 billion in 2022 to an estimated EUR 4 billion by 2026. With the introduction of macrocarriers, this growth is expected to accelerate even further.

Introducing Cellevat3d® upstream product portfolios

Cellevate is responding to exactly these needs by offering innovative cell culture systems readily scalable from lab- to production-scale. These products are designed for highest yield and enhanced productivity.

The Cellevat3d® platform features two distinct product portfolios for industrial cell culture – Cellevat3d® nanofiber microcarriers and Cellevat3d® nanofiber macrocarriers – each tailored to specific needs, both engineered to revolutionize upstream bioprocessing and increase patient access to life-changing therapies such as cell and gene therapy and novel vaccines.

Cellevat3d®

– 1 platform, 2 upstream product lines

Our first upstream product line – Cellevat3d® nanofiber microcarriers – is designed for stirred tank bioreactor applications such as gene therapy, pluripotent stem cells (PSCs), organoid formation as well as HEK-based recombinant proteins and vaccines.

The second product line in development – Cellevat3d® nanofiber macrocarriers – is aimed for packed-bed and fixed-bed bioreactors applications, including cell therapy, vaccine production, recombinant proteins, and organoid formation.

Cellevat3d® nanofiber microcarriers

| Material | Cellulose nanofibers |

| Format | Monofibers |

| Bioreactor | Stirred tank bioreactors |

| Applications | Gene therapy, PSC’s, HEK based recombinant proteins, HEK based vaccines, organoid formation |

microcarriers

Cellevat3d® nanofiber macrocarriers

| Material | Cellulose nanofibers |

| Format | Cross-linked fibers |

| Bioreactor | Packed- & fixed-bed bioreactors |

| Applications | Cell therapy, MSC’s, vaccines, recombinant proteins, organoid formation |

4 reasons to choose Cellevat3d® products

Up to 60 times larger surface area

Our nanofiber-based Cellevat3d® microcarriers provide unmatched surface area for cells to grow compared to current options.

More than 3 times viral vector yield

Through the formation of homogenous spheroids, Cellevat3d® nanofibers create a true three-dimensional cell culture environment. This generates significantly higher viable cell densities and viral vector yields in stirred tank bioreactors compared to current solutions.

Easy to use and easy to scale

Cellevat3d® nanofiber-based cell culture systems are easy to implement into your processes and can be scaled from cell culture flasks all the way to large, stirred tank bioreactors.

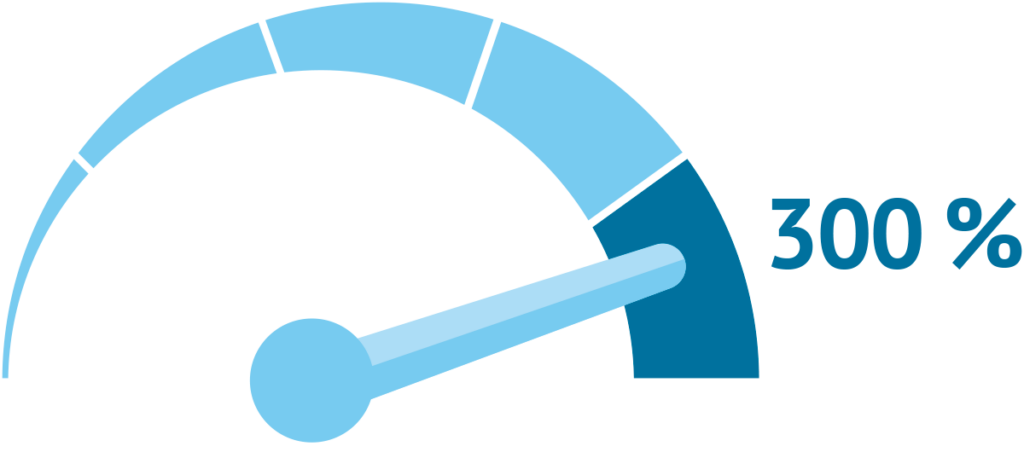

More than 300% increase in viral vector productivity and improved process economy

Cellevat3d® nanofiber-based products enable improved cell culture product yield, faster processes, and very efficient scale-up, vastly improving overall process economy.